Product description

– filling cavities and levelling other irregularities in the substrate,

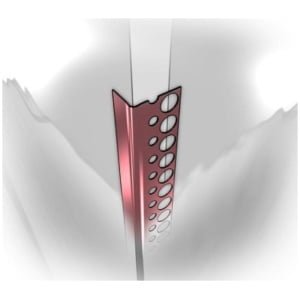

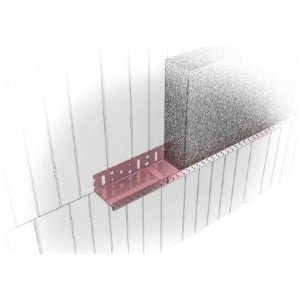

– corner reconstruction,

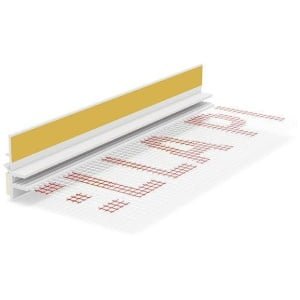

– filling grooves left by decommissioned installations both in floors and walls, after point or line drains,

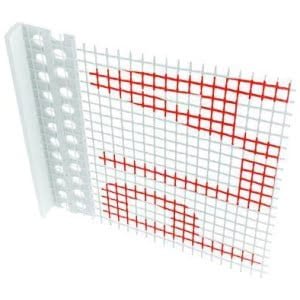

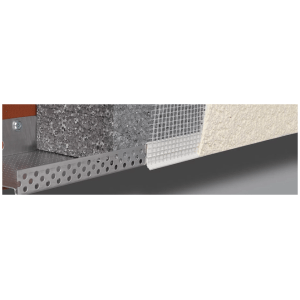

– full-surface levelling of walls including plastering up to 3 cm,

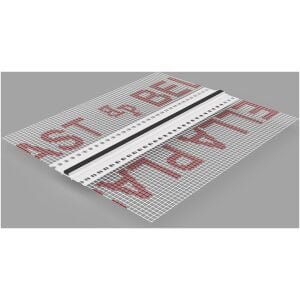

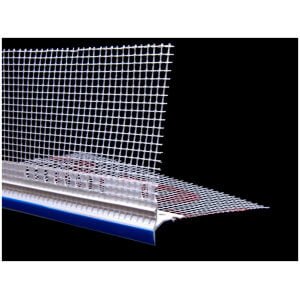

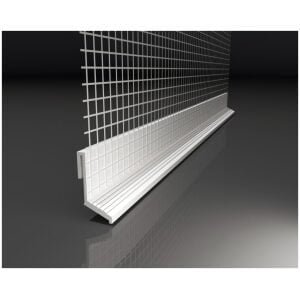

– additional thick surface reinforcement using glass fibre mesh,

– repair of window reveals when replacing joinery,

– repair of balcony slab edges, corners of beams, columns and stairs, restorations and repairs to floors,

– shaping facets,

– plaster restoration,

– formation of slopes in linear drains, terrace and balcony sleepers,

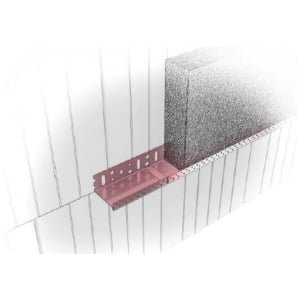

– masonry restorations at penetrations through the building wall.

• Making subfloors bonded to the subfloor.

• Type of substrate to be repaired – cement and cement-lime plaster, concrete, aerated concrete, cement screeds, as well as unplastered brick and ceramic or silicate block walls.

• Type of finishing layer – ceramic tile cladding, plaster, thin layer plaster, floor panels, etc.

Main properties

- Allows a very quick start to subsequent work – under normal conditions, the tiles can be laid after approx. 5 hours (at a layer thickness of 5 mm).

- Reduces wear and tear on adhesive mortars, plasters and floor underlays and flooring.

- Plastic consistency – the working parameters ensure easy application and the desired filling of cavities in the repaired surface.

- High mechanical strength:

– compressive min. 20 MPa

- – bending min. 4.0 MPa.

- Reinforced with polypropylene fibres that:

– reduce cracks resulting from shrinkage during mortar setting,

- – allow thicker layers of mortar to be applied to vertical surfaces without run-off effect,

- – ensure even water transport during drying.

- No shrinkage cracks.

- A wide range of layer thicknesses – from 3 to 30 mm in one pass – moreover, when mixed with quartz sand (grain size up to 2 mm) at a weight ratio of 1:4 (sand : dry mortar), layer thicknesses of 31 mm to 60 mm can be extended (when filling cavities and levelling horizontal surfaces).