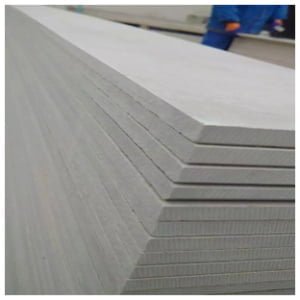

EPS BOARD (polystyrene board) for externall wall insulation

50mm Grey Polystyrene (Graphite EPS) for External Wall Insulation – SINGLE BOARD

50mm Grey Polystyrene (Graphite) is a high quality expanded polystyrene (EPS) board enhanced with integrated graphite within its bead structure and of grey colour used for external wall insulation. The high-purity graphite particles integrated within the insulation beads reflects radiant heat and significantly improves insulation capability, providing up to 20% greater r-value than traditional white EPS of the same thickness. The rigid EPS closed-cell insulation traps air in pockets within each bead when formed. Air trapped in these pockets is a poor conductor of heat, and therefore slows down its transfer towards cooler air.

Grey Polystyrene (Graphite) boards have high-purity graphite particles infused into its cell structure that give it a reflective property and a distinctive dark grey colour. As radiant heat moves through graphite insulation, it reflects it hundreds of times, significantly slowing down the transfer of heat and making it more energy efficient.

Warm air always moves towards cold air, but in Grey Polystyrene (Graphite) boards. that path takes many twists and turns along the way, slowing down the heat transfer, keeping the premises warmer. This improves its thermal conductivity to 0.031 W/mK, an improvement over standard expanded polystyrene boards.

- Lightweight,

- Easily cut with a sharp knife to any size and shape,

- High resistance to mold growth,

- Highly durable, if used according to specifications,

- Cost efficient,

- An environment friendly Green Way product.

- New and existing rendered or unrendered masonry,

- Timber backed walls, floors and roofs.

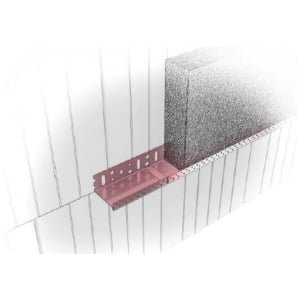

- Cavity wall construction.

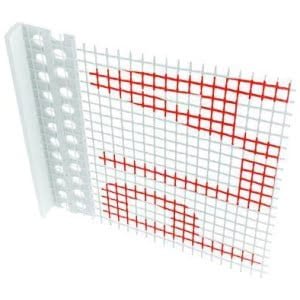

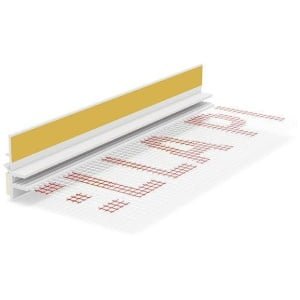

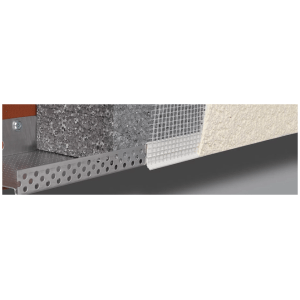

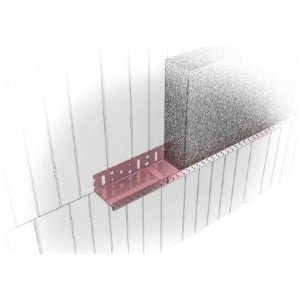

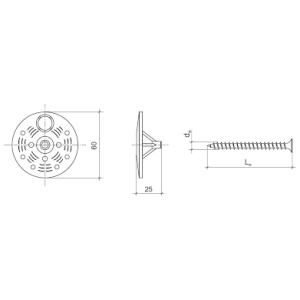

- The boards are initially fixed to the substrate (masonry or timber) either by a mortar/adhesive or simply by mechanical fixings, or with adhesive as well as mechanical fixings.

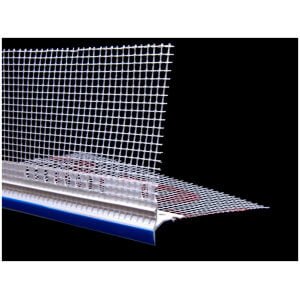

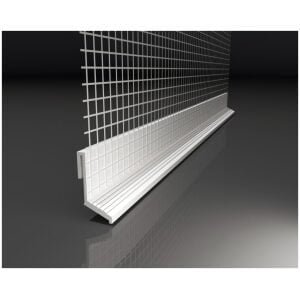

- Then the boards should be covered with an outer layer, siding or by a mortar layer.

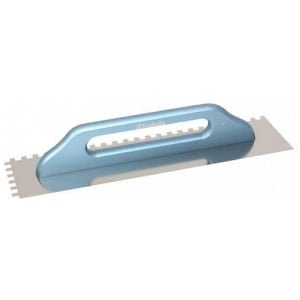

- The outer surface of the board needs to be rasped or sanded down to produce an abrasive surface, before covering it with the fibre mesh, to which the base coat or mortar layer would be applied.

Produced to the requirements of EN-13163 Standard.