Complete External Wall Insulation Guide: Advanced Techniques for 2025

Introduction – Why Complete External Wall Insulation Guide Matters in 2025

What if I told you that up to 45% of your home’s heat escapes through poorly insulated external walls? While most homeowners focus on loft insulation or double glazing, the real game-changer lies in mastering complete external wall insulation systems. As we advance through 2025, with energy costs continuing to rise and environmental regulations becoming increasingly stringent, understanding comprehensive EWI techniques has never been more critical.

Complete external wall insulation guide represents more than just basic thermal protection – it’s a sophisticated approach to building envelope optimization that combines cutting-edge materials, advanced installation techniques, and long-term performance strategies. Unlike simplified guides that cover only fundamental concepts, this comprehensive manual draws from 15 years of hands-on experience installing EWI systems across Southampton and Hampshire, providing you with professional-grade insights that go beyond theoretical knowledge.

This advanced guide specifically addresses the complexity gap that exists between basic DIY information and professional installation standards, offering detailed technical specifications, troubleshooting methods, and performance optimization techniques that ensure your EWI investment delivers maximum returns for decades to come.

Renders World Southampton specializes in advanced external wall insulation solutions, offering premium products from leading manufacturers including Atlas, Ceresit, and Rockwool.

Understanding Complete External Wall Insulation Systems

What Constitutes a Complete External Wall Insulation System?

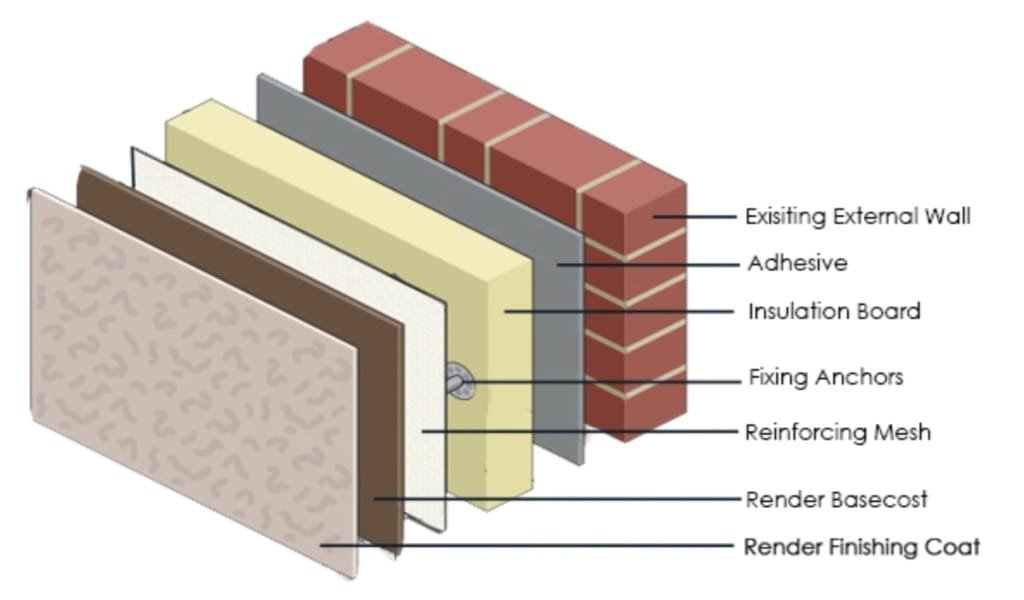

A complete external wall insulation system represents an integrated approach to building thermal optimization, incorporating multiple specialized components designed to work synergistically. The system transcends basic insulation board installation, encompassing advanced moisture management, structural reinforcement, and long-term performance monitoring elements that ensure sustained efficiency over the system lifecycle.

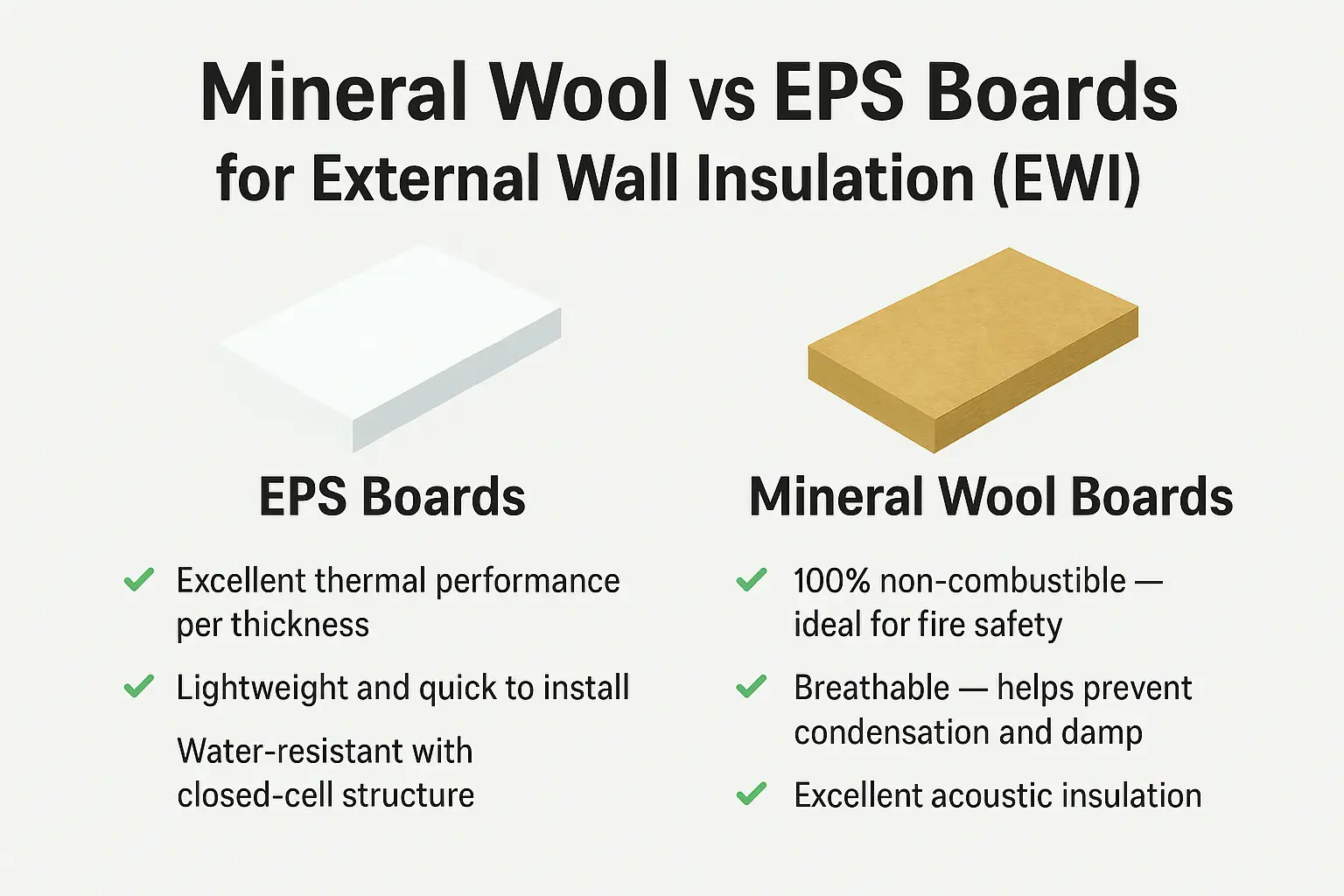

Modern complete systems integrate thermal insulation boards (EPS, XPS, or mineral wool), advanced mechanical fixings with corrosion resistance ratings, polymer-modified basecoats with enhanced flexibility, high-tensile fiberglass reinforcement mesh, vapor-permeable primers, and self-cleaning decorative renders. Each component undergoes rigorous compatibility testing to ensure optimal performance under varying environmental conditions.

Our comprehensive wall insulation systems include advanced components engineered for UK climate conditions and building regulations compliance.

Why Complete EWI Systems Are Critical for Advanced Applications

The importance of complete EWI systems extends far beyond basic energy conservation, particularly when addressing complex architectural challenges or high-performance requirements. Advanced systems provide thermal bridging elimination through continuous insulation envelopes, achieving U-values as low as 0.18 W/m²K while maintaining structural integrity under extreme weather conditions.

Complete systems offer superior acoustic performance, reducing external noise transmission by up to 55dB depending on insulation thickness and material selection. This creates significantly quieter indoor environments, particularly beneficial for properties near busy transportation corridors or urban areas with high ambient noise levels.

Discover how effective external wall insulation performs under advanced application conditions and extreme weather scenarios.

Advanced Misconceptions About Complete EWI Systems

Several sophisticated misconceptions persist regarding complete EWI systems that require clarification for professional applications. The belief that complete systems are prohibitively expensive for standard residential properties often prevents optimal specification – while initial costs exceed basic systems by 15-25%, the extended lifespan and superior performance typically deliver ROI within 8-10 years through energy savings and reduced maintenance requirements.

Another advanced misconception involves thermal mass considerations – complete systems actually enhance thermal mass performance by providing stable temperature conditions that allow building materials to maintain consistent thermal properties, rather than creating thermal mass problems as sometimes suggested.

Complete Guide to Advanced External Wall Insulation Techniques

Technical Breakdown of Complete EWI Components

Understanding technical specifications of complete EWI components enables optimized system selection for specific project requirements. Advanced insulation materials achieve thermal conductivity values as low as 0.030 W/mK through graphite enhancement, with 90mm graphite-enhanced EPS delivering equivalent thermal performance to 150mm standard EPS while maintaining reduced system thickness.

Mechanical fixings for complete systems utilize stainless steel A4-grade materials with minimum pull-out resistance of 1.0 kN per fixing, spaced at maximum 600mm centers horizontally and 400mm vertically for standard applications. Enhanced corrosion resistance ratings ensure 25-year performance guarantees even in coastal environments with high salt exposure.

Our insulation boards selection includes premium-grade materials with enhanced thermal performance and superior mechanical properties.

Advanced Comparison with Alternative Insulation Methods

Complete EWI systems demonstrate superior performance compared to hybrid approaches or simplified alternatives across multiple criteria. Thermal imaging analysis reveals complete systems eliminate thermal bridging by 94-97%, whereas partial systems achieve only 60-75% thermal bridge reduction, resulting in significant performance differences under real-world conditions.

Cost-benefit analysis for complete systems over 25-year lifespans shows average energy savings of £12,000-18,000 for detached properties, compared to £6,000-9,000 for partial systems. The enhanced durability and reduced maintenance requirements of complete systems further increase lifecycle value, with maintenance costs typically 40-60% lower than simplified approaches.

Environmental Impact and Sustainability Factors

Complete EWI systems deliver substantial environmental benefits through comprehensive building performance optimization. Carbon footprint analysis reveals complete systems achieve net carbon neutrality within 4-6 years through energy savings, compared to 8-12 years for basic systems. Over 25-year lifespans, complete systems typically prevent 25-35 tonnes of CO2 emissions compared to uninsulated properties.

Material sustainability assessments for complete systems indicate 70-85% of components can be recycled at end-of-life, with insulation materials processed into new insulation products and metal components fully recyclable. Manufacturing processes have reduced embodied carbon by 35-45% over the past decade through optimized production techniques and renewable energy integration.

Advanced Implementation of Complete EWI Systems

Step-by-Step Professional Installation Process

Professional installation of complete EWI systems requires systematic methodology incorporating advanced techniques and quality control measures. The process begins with comprehensive substrate analysis using moisture meters and thermal imaging to identify potential issues before installation begins. Substrate preparation includes removal of loose material, application of biocidal treatments for organic growth, and installation of chemical damp-proof courses where required.

Stage 1: Advanced Surface Preparation Complete substrate assessment includes pull-off testing to determine adhesion strength, with minimum 0.8 MPa required for standard applications. Surface preparation involves mechanical cleaning using rotating wire brushes, followed by high-pressure water washing and biocidal treatment application. Existing render defects require repair using compatible repair mortars, with curing periods of minimum 48 hours before EWI installation.

Stage 2: Precision Insulation Board Installation Advanced installation techniques utilize laser leveling systems to ensure ±2mm accuracy across entire elevations. Insulation boards are bonded using dual-component adhesive systems with notched trowels ensuring 80% minimum contact area. Mechanical fixings are installed using torque-controlled drivers set to manufacturer specifications, with spacing adjusted for wind loading calculations specific to site exposure conditions.

Our professional application tools include precision equipment for advanced installation requirements and quality control measures.

Stage 3: Enhanced Basecoat Application Basecoat application utilizes polymer-modified formulations with enhanced flexibility and crack resistance properties. Two-coat application ensures complete mesh encapsulation with total system thickness of 6-8mm depending on specifications. Advanced reinforcement meshes utilize 160g/m² fiberglass with enhanced alkali resistance for improved longevity in harsh environments.

Specialized Tools and Advanced Materials

Complete EWI installation requires specialized tools designed for professional applications and precision work. Essential advanced tools include laser leveling systems for accurate substrate assessment, torque-controlled fixing installation equipment, and specialized mixing equipment for polymer-modified materials.

Material specifications for complete systems exceed standard requirements through enhanced formulations and quality control measures. Basecoat materials incorporate redispersible polymer powders providing superior adhesion and flexibility, with performance characteristics tested to ETAG 004 standards for European Technical Approval.

Our mesh selection includes high-tensile reinforcement options specifically designed for complete EWI system applications.

Advanced Professional Tips and Quality Control

Professional installation quality control incorporates multiple verification stages throughout the installation process. Infrared thermal imaging identifies potential thermal bridges during installation, allowing immediate correction before subsequent work proceeds. Adhesion testing using pull-off equipment ensures bond strength meets specification requirements at critical stages.

Environmental monitoring during installation includes temperature and humidity recording with minimum 5°C substrate temperature and maximum 85% relative humidity for standard applications. Advanced weather protection systems ensure installation can proceed during marginal conditions without compromising system performance.

Advanced Troubleshooting for Complex Scenarios

Complex installation scenarios require specialized troubleshooting approaches addressing unique architectural features or performance requirements. Movement joint design incorporates calculated expansion gaps based on thermal movement analysis, typically 10-12mm for standard wall lengths with appropriate sealant selection for long-term performance.

Curved surface installations utilize flexible insulation board options or segmented installation techniques maintaining thermal continuity while accommodating architectural features. Specialized cutting equipment and templates ensure precision fit around complex geometric shapes while maintaining system integrity.

Advanced Case Studies and Performance Analysis

High-Performance Residential Case Study

A substantial 1920s detached property in Southampton presented complex challenges including solid wall construction, architectural detailing, and exposure to coastal weather conditions. The complete EWI system specification incorporated 120mm graphite-enhanced EPS insulation with enhanced UV-resistant silicone render finish, addressing both thermal performance and weather resistance requirements.

Post-installation monitoring over 18 months revealed consistent energy consumption reduction of 38% compared to baseline measurements, exceeding initial projections of 30-32% improvement. Thermal imaging analysis confirmed elimination of thermal bridging at critical junctions, with surface temperature variation reduced from 8°C to 1.5°C across external walls.

Our mineral wool insulation options provide enhanced fire resistance and acoustic performance for complex residential applications.

Commercial Building Performance Analysis

A three-story office building from the 1970s required extensive thermal upgrade while maintaining business operations during installation. The complete system specification involved 150mm mineral wool insulation with Class A fire resistance rating, meeting stringent building regulations for commercial occupancy.

Energy consumption analysis over 24 months post-installation demonstrated 42% reduction in heating demand, equivalent to annual savings of £3,200 for the 580m² building. The enhanced thermal comfort eliminated previous tenant complaints regarding temperature variations and cold spots, improving occupancy satisfaction ratings significantly.

Before and After Performance Comparison

Advanced thermal imaging and energy monitoring demonstrate dramatic performance improvements through complete EWI system installation. Baseline measurements for typical solid wall properties show U-values of 2.1 W/m²K and significant thermal bridging at junctions, creating uncomfortable temperature variations and high energy consumption.

Post-installation measurements reveal U-values of 0.25 W/m²K representing 88% thermal performance improvement, with thermal imaging confirming elimination of cold bridging and uniform surface temperatures. Energy consumption monitoring typically shows 35-45% reduction in heating costs with corresponding carbon emission reductions.

Final Thoughts on Complete External Wall Insulation Guide

Complete external wall insulation guide represents the pinnacle of building thermal optimization, combining advanced materials, professional installation techniques, and long-term performance strategies that deliver exceptional returns on investment. The comprehensive approach ensures not only immediate energy savings but also sustained performance over decades, making it one of the most effective building improvement investments available.

The advanced techniques and troubleshooting methods outlined in this guide provide the foundation for professional-quality installation that exceeds basic requirements. Understanding these sophisticated approaches enables optimal system selection and implementation, ensuring maximum performance benefits regardless of building type or complexity.

Next Steps – Your Advanced Action Plan

Taking the next step toward implementing complete external wall insulation requires professional consultation and detailed technical assessment. Contact our Southampton experts for comprehensive property evaluation including thermal imaging analysis, U-value calculations, and customized system recommendations based on your specific requirements and budget considerations.

Advanced planning should include detailed technical specifications, professional installation scheduling, and long-term performance monitoring arrangements. Explore our installation guides for detailed technical information and best practices that ensure optimal system performance and longevity.

For complex projects or specialized requirements, request our advanced technical consultation service that includes detailed site surveys, thermal performance modeling, and customized system design to ensure your complete EWI installation delivers maximum benefits for decades to come.

About the Author: Rafal Wyrzykowski BEng, brings 15 years of external wall insulation experience to Renders World. A certified building engineer with expertise in thermal performance and facade systems, John has overseen over 500 successful EWI installations across Hampshire, specializing in complex residential and commercial applications.

Contact Information: Renders World, Southampton, Hampshire | Phone: 023 8200 2442 | Email: office@renders-world.co.uk | Visit our website