WhiteTeq Pro Thermal and Sound Insulation Foam – 750ml

Ceresit WhiteTeQ is white polymer foam of a new generation polyurethane, based on purified and concentrated ingredients to achieve improved performance. The WhiteTeQ polymer purification Technology gives the foam its characteristic ice-white colour, an extra-fine cell structure and enhanced UV resistance. The cured foam has highest thermal efficiency (up to 0,032 W/mK) and sound damping properties (63 dB). It also has unrivalled low curing pressure for maximum protection against frames deformation and 25 % flexibility ensures a long-term insulation efficiency, compensating the movements of the seal resulted from thermal expansion. The perfect ratio of open and closed cells and mechanical strength makes it the perfect product for demanding insulation applications. The foam has excellent adhesion on most building materials like wood, concrete, stone, metal. This foam does not contain CFC-propellants.

- Excellent Thermal Insulation (down to 0,030 W/mK),

- Maximum Sound Protection (63dB),

- High Durability and flexibility (>25%),

- Low Curing pressure,

- Superior UV Resistance (10X Better), Does not contain CFC-propellants.

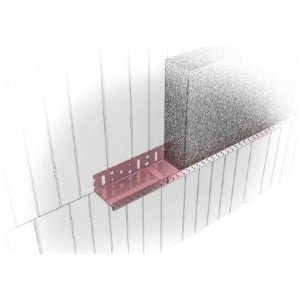

- Insulation of window frames,

- Insulation of door frames,

- Filling of cavities,

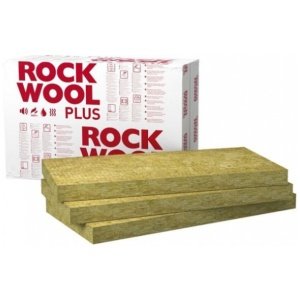

- Sealing of openings in roof constructions and insulation materials,

- Creating soundproof screens,

- Filling of cavities around pipes,

- Fixing of roof tiles and wall panels

- Substrates must be stable, clean and free of substances likely to impair adhesion.

- To ensure full and even curing of the foam, moisturise slightly mineral, porous substrates (brickwork, concrete, limestone) with water spray before application.

- Mask off adjacent areas with foil.

- The surfaces can be moist, but not frosted or iced.

- If the temperature indicator had turned blue, the container is too cold for usage. Warm up the container in a warm room or in warm water. For best results keep the container at room temperature during application.

- Shake the container vigorously before use (15 – 20 times).

- Remove the plastic cap from the container and screw it tightly onto the gun. When working with the gun always keep the container upside down. The outflow rate of the foam is controlled by pressing gun trigger.

- Dispense the foam sparingly to avoid excess overflows.

- Repeat shaking regularly during application.

- It is not recommendable to remove the container before it is totally empty. When replacing the container shake the new can vigorously.

- Unscrew the empty container and replace it immediately to ensure that there is no air left in the gun.

- If you do not want to replace the container, remove the foam from the gun using PU foam cleaner. Hardened foam can only be removed mechanically.