As energy prices remain high and the updated Part L Building Regulations 2025 demand ever-lower U-values, EPS insulation boards UK installers and homeowners overwhelmingly choose graphite-enhanced expanded polystyrene. In 2025, over 80% of all external wall insulation systems in Britain use EPS insulation boards UK – and the reasons are clear: unbeatable thermal performance, ease of installation and the lowest lifetime cost.

This definitive 2025 expert guide covers everything you need to know about EPS insulation boards in the UK: the latest technology, real-world advantages over mineral wool and XPS, accurate U-value calculations, proven energy savings, grant eligibility (ECO4 & Great British Insulation Scheme) and why graphite EPS remains the undisputed king of British solid-wall retrofits.

What Exactly Are EPS Insulation Boards?

EPS insulation boards UK are rigid, lightweight thermal insulation panels manufactured from expanded polystyrene beads. Consisting of 98% trapped air in a closed-cell structure, they deliver outstanding insulation at minimal weight and cost. All boards sold in the UK comply with BS EN 13163:2012+A2:2016.

Today there are two main types on the market:

- Standard white EPS (λ ≈ 0.038 W/mK)

- Graphite-enhanced grey EPS (λ ≈ 0.031–0.032 W/mK) – the professional’s choice in 2025

How Modern EPS Insulation Boards Are Made (Step-by-Step)

- Polystyrene beads containing pentane (zero ODP, low GWP) are pre-expanded with steam

- Maturation period of 6–24 hours

- Graphite particles are added (grey EPS only) + block moulding under pressure

- Blocks are wire-cut to exact thickness

- Final testing: compressive strength ≥ 100 kPa, lambda value, dimensional stability

Key Advantages of EPS Insulation Boards UK in 2025

| Advantage | Technical Detail | Real-World Benefit (UK) |

|---|---|---|

| Best performance-to-price ratio | λ = 0.031 W/mK (graphite) | Achieve 0.18 W/m²K on solid brick with just 160 mm |

| Ultra lightweight | <3 kg per 1200×600 mm board | Faster, safer installation – less fatigue |

| Proven 50+ year lifespan | FIW Munich independent studies | No measurable thermal degradation when rendered |

| Full grant eligibility | ECO4, GBIS, LA Flex | Up to 100% funded for qualifying homes |

| Breathable & hydrophobic | Closed-cell yet vapour permeable | Eliminates damp & black mould |

Honest Limitations & How Professionals Overcome Them

| Limitation | Professional Solution |

|---|---|

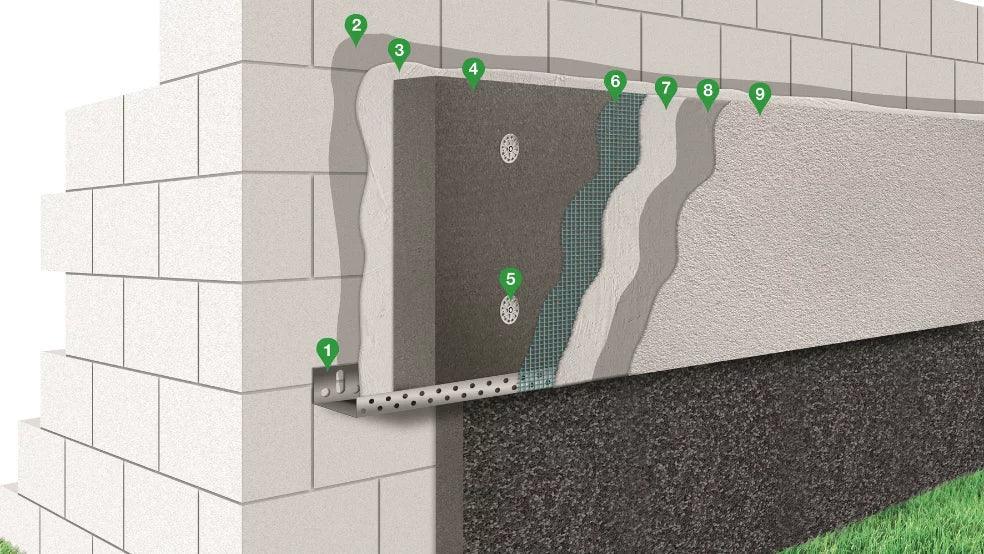

| Euroclass E fire rating (unrendered) | Use certified full system → B-s1,d0 once rendered |

| Not suitable below DPC | Switch to XPS for plinth/foundation zones |

| Potential bird pecking | Render within 48 hours of boarding |

EPS vs XPS vs Mineral Wool vs Phenolic – 2025 UK Comparison

| Material | λ Value | Typical Cost | Best UK Application |

|---|---|---|---|

| Graphite EPS | 0.031–0.032 | ££ | 90% of domestic solid-wall retrofits |

| Standard White EPS | 0.038 | £ | Budget projects |

| XPS | 0.033–0.038 | £££ | Plinths & high-compression areas |

| Mineral Wool | 0.032–0.037 | ££££ | High-rise or A-rated fire requirement |

| Phenolic | 0.018–0.021 | £££££ | Passivhaus thin-profile only |

Real Energy Savings & Indoor Comfort Improvements

A typical 1930s semi-detached house retrofitted with 140 mm graphite EPS insulation boards UK and silicone render achieves:

- Annual heating bill savings: £680–£950 (2025 prices)

- Indoor temperature rise: +4–6 °C without increasing thermostat

- Complete elimination of condensation and black mould

- Summer overheating reduction by 15–20 % (graphite reflection)

- Payback period: 4–7 years (or <3 years with grants)

Ready to Start Your Project?

Contact the Renders World team in Southampton today for:

- Free U-value calculations

- ECO4 / Great British Insulation Scheme eligibility check

- Next-day UK delivery of premium graphite EPS boards