SIATKA Z WŁÓKNA SZKLANEGO

2 produktów

Wyświetlanie 1 - 2 z 2 produktów

Fibreglass Mesh UK – High-Strength Reinforcement for Rendering

Renders World is a specialist supplier of professional fibreglass mesh UK, providing the essential "skeletal" reinforcement required for all modern External Wall Insulation (EWI) and thin-coat render systems. Designed to absorb the structural tensions caused by thermal expansion and the unpredictable UK weather, our fibreglass rendering mesh UK ensures a crack-free, impact-resistant finish. Whether you are installing a high-performance silicone system or traditional scratch render, our alkali-resistant mesh range offers the tensile strength needed to maintain facade integrity for decades.

Technical Performance & Structural Integrity

In the professional construction sector, the quality of the reinforcement layer determines the longevity of the entire project. Our collection features heavy-duty 150g rendering mesh price UK options and 160g high-grammage rolls, providing superior resistance to mechanical stress and chemical erosion from cement-based adhesives. For compliance with UK building insurance and warranty standards, always ensure your reinforcement layer is fully embedded within the basecoat.

| Property | Specification / Standard |

|---|---|

| Material Type | E-Glass Fibreglass (Alkali-Resistant Coating) |

| Grammage | 150g/m² / 160g/m² (System Dependent) |

| Roll Dimensions | 1.0m / 1.1m x 50m (50m² - 55m² coverage) |

| Tensile Strength | ≥ 2000 N/50 mm (Initial) |

| Compliance | ETAG 004 / BBA System Compatible |

Key Benefits of System Reinforcement

- Crack Prevention: Effectively neutralizes tension from freeze-thaw cycles and direct solar heating.

- Alkali Resistance: Specialized polymer coating protects the glass fibers from the high pH levels of cementitious mortars.

- Impact Protection: Significantly increases the facade’s resistance to dents and mechanical damage in high-traffic areas.

- Universal Compatibility: Fully tested for use with Atlas Hoter U, Ceresit ZU, and all premium silicone renders.

The 100mm Overlap Rule

To ensure a continuous reinforced surface and avoid vertical stress cracks, all mesh strips must be overlapped by a minimum of 100mm (10cm). Our mesh rolls feature printed markers to guide installers, ensuring that weak points are eliminated at the joints. For detailed technical guidance on proper embedding techniques, please consult our Fibreglass Mesh Overlap Guide.

Is This Mesh Suitable for Your System?

- Choose this product if: You are installing a thin-coat render system over EPS, Mineral Wool, or carrier boards and require a BBA-compliant reinforcement layer.

- Note: For high-impact zones (plinths), we recommend doubling the mesh layer or using our specialized high-impact heavy mesh variants.

Frequently Asked Questions

What is the difference between 150g and 160g mesh?

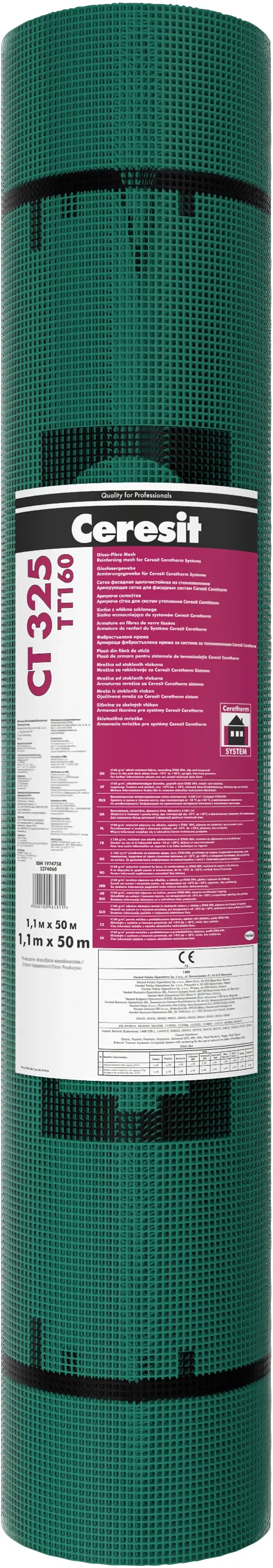

While both provide excellent reinforcement, 160g mesh (such as Ceresit CT325) offers higher tensile strength and is often the mandatory requirement for certified EWI systems to meet specific impact resistance ratings.

Can I use internal plastering mesh for external rendering?

No. Internal mesh often lacks the heavy-duty alkali-resistant coating required to survive the chemical environment of external basecoat mortars. Using internal mesh externally will lead to system failure.

Complete your reinforcement layer by browsing our range of compatible render corner beads with mesh and insulation adhesives. Source your supplies from Renders World for trade prices and nationwide next-day delivery.